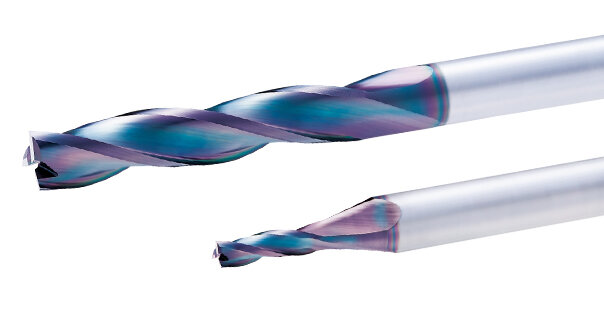

SEP-EL

DLC Coated Carbide End Mill for Super Engineering Plastics

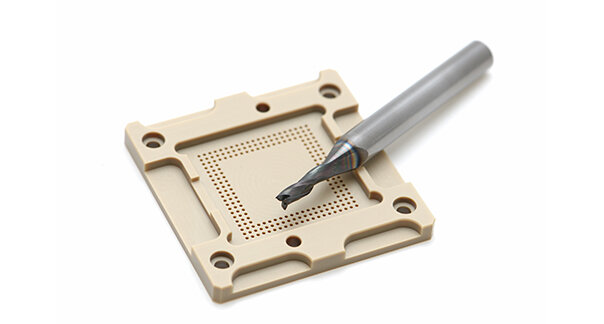

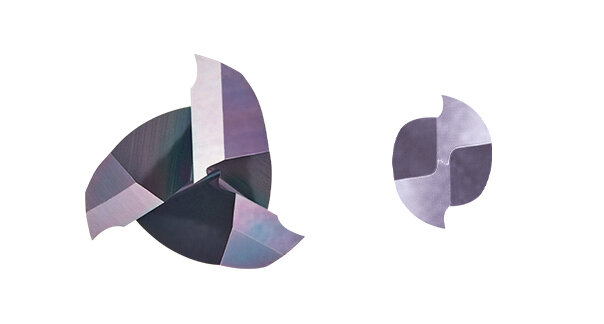

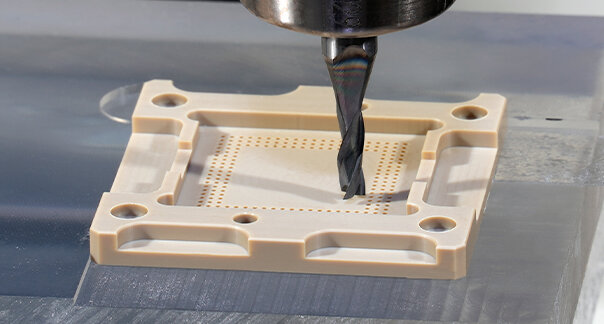

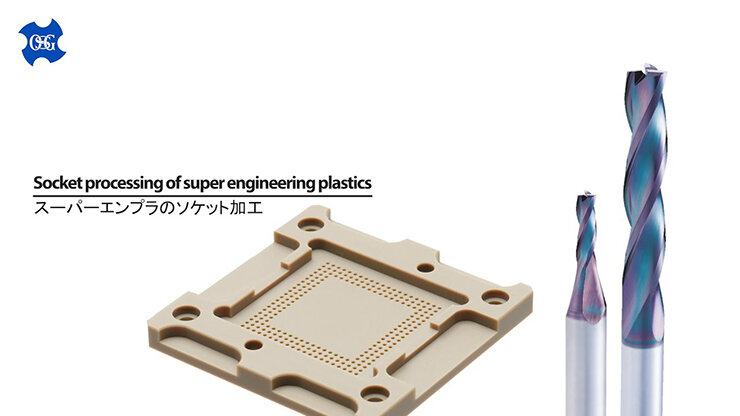

The SEP-EL DLC coated carbide end mill is specifically designed for “super engineering plastics,” known for their exceptional heat resistance and mechanical strength. Its thick DLC-IGUSS coating significantly reduces wear at the cutting edge, leading to excellent adhesion resistance and extended tool life.Items with a 1 mm or larger outer diameter feature a 3-flute design for high-efficiency machining. The SEP-EL's sharp cutting edge and optimized flute shape deliver outstanding cutting performance and chip removal, while also suppressing burr formation. This combination makes it an ideal solution for intricate resin applications and rigorous precision specifications.

Features

DLC-IGUSS coating

DLC-IGUSS coating

3-flute specification for highly efficient machining

3-flute specification for highly efficient machining*2-flute for outer dia. 0.5 mm

Cutting edge design with emphasis on sharpness allows for high-quality resin processing

Cutting edge design with emphasis on sharpness allows for high-quality resin processing

Flute shape optimized for resin processing reduces burrs

Flute shape optimized for resin processing reduces burrs

Excellent cutting edge diameter tolerance of 0.015 mm allows for strict machining dimensional accuracy

Excellent cutting edge diameter tolerance of 0.015 mm allows for strict machining dimensional accuracy

Applications

Plastic・Thermoplastic Resin・Thermosetting Resin・Copper Alloy・Aluminum Alloy

Lineup

3 × D cutting length

- Sharp Corner Edge Type φ0.5~φ6

5 × D cutting length

- Sharp Corner Edge Type φ0.5~φ6

Others

-

High performance type (AE-VTS-N) and standard type (AE-TS-N・AE-TL-N) DLC coated carbide end mills effective for non-ferrous materials such as resin are also available.

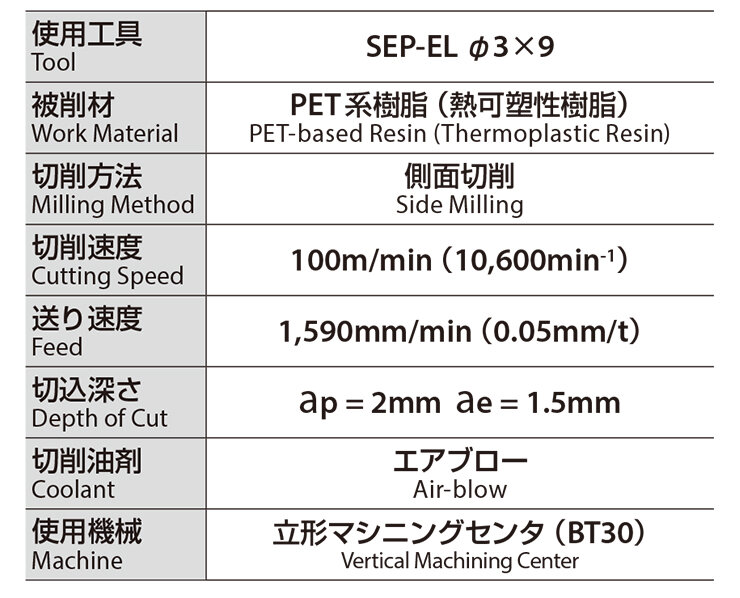

Data

Flute specification optimized for resin processing to reduce the occurrence of burrs