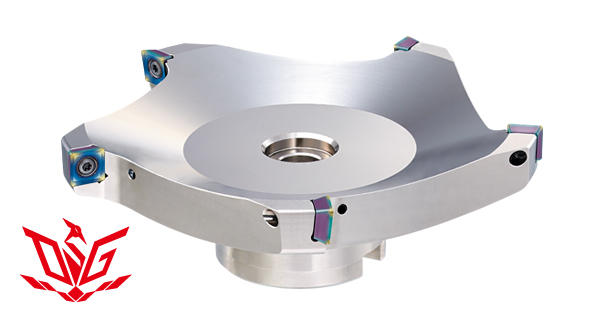

PFDC

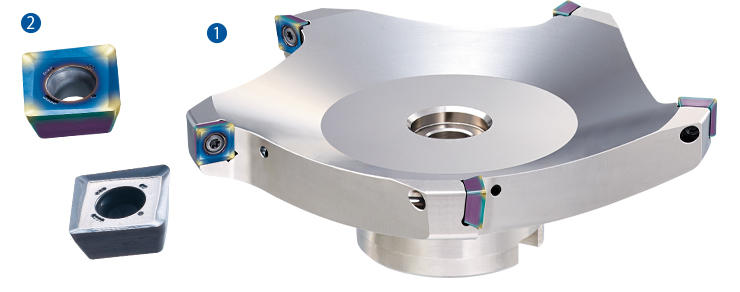

The PFDC is a lightweight large-diameter disc cutter that can be mounted on small machining centers. Due to its wide cutting width, the PFDC is able to achieve uniform machined surface with no seams in 1-pass, which is difficult to achieve with conventional small machining centers. With the expansion of single crystal diamond inserts, mirror finishing of non-ferrous metals and highly transparent resin processing is made possible.

Features

- φ125 can be used with BT30

- No special arbor required for easy tool management

- Balance grade G6.3 is guaranteed for the cutter body (with inserts installed)

Thin steel body: lightweight and high tool rigidity

Thin steel body: lightweight and high tool rigidity

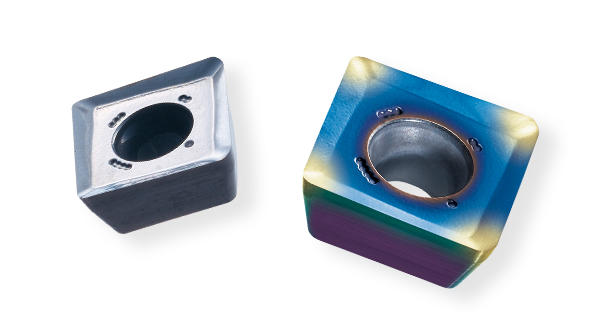

- Economical 4-corner insert with 90°cutting angle

Inserts suitable for non-ferrous metal and resin machining

Inserts suitable for non-ferrous metal and resin machining・Insert grade XP4610 (DLC coating) suitable for resin machining and long tool life in non-ferrous metal machining

・Insert grade DM001 (single crystal diamond) that allows mirror finishing of non-ferrous metals and highly transparent resin machining

Applications

Aluminum Alloy・Thermoplastic Resin (XP4610 recommended)・Thermosetting Resin (XP4610 recommended)

Lineup

φ80~φ125

Data

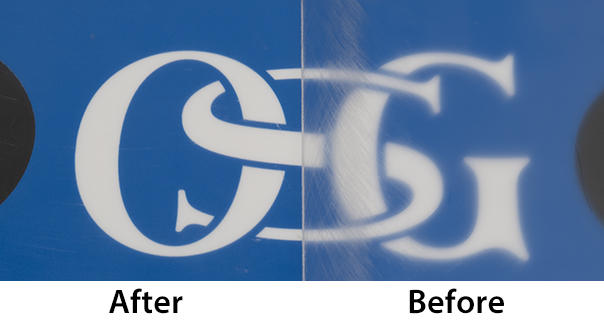

[Thermoplastic resin] Good machined surface accuracy with reduced cutting heat

![[Thermoplastic resin] Good machined surface accuracy with reduced cutting heat](../images/spe_pfdc_date01.jpg)

![[Thermoplastic resin] Good machined surface accuracy with reduced cutting heat](../images/spe_pfdc_date02.jpg)

The XP4610 suppresses cutting heat due to the effect of the DLC coating, enabling good surface finish in low melting point plastics.