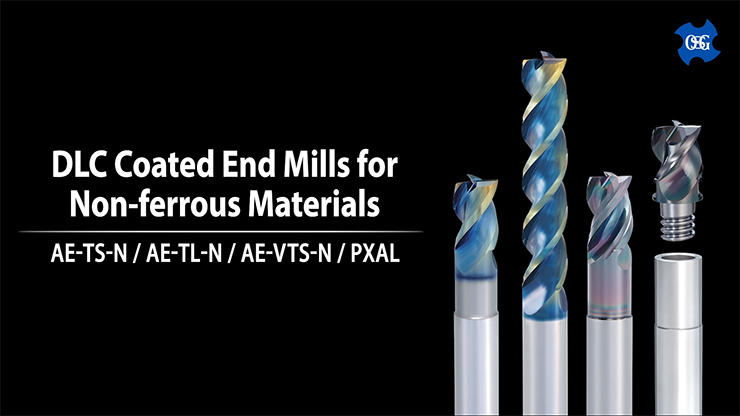

AE-TS-N・AE-TL-N

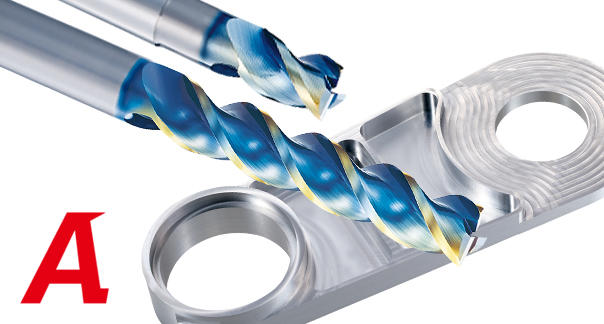

The AE-TS-N and AE-TL-N DLC coated carbide end mills for non-ferrous materials are extremely effective for non-ferrous materials such as aluminum alloys that require welding resistance and lubricity with the DLC-SUPER HARD coating. With excellent cutting sharpness, these end mills are able to suppress burrs to achieve excellent surface finish. This end mill series is available in square, sharp corner edge and radius types to accommodate a wide range of fields, from part processing to applications in the aerospace industry. In addition, dia. 1 mm to 2.5 mm have been added to the lineup of the square type and sharp corner edge type to support precision machining of small diameter sizes.

High performance type (AE-VTS-N) DLC coated carbide end mill for non-ferrous materials is also available.

Features

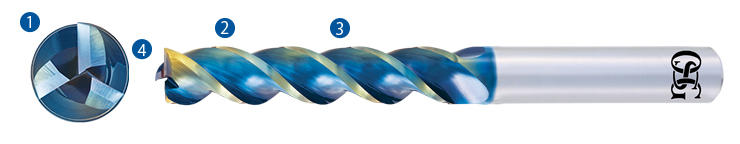

DLC-SUPER HARD coating

DLC-SUPER HARD coating

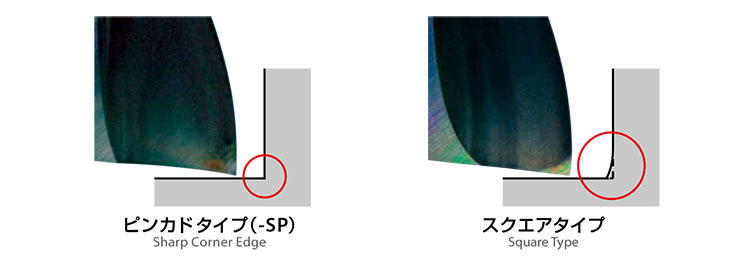

Cutting edge specification that achieves both rigidity and sharpness

Cutting edge specification that achieves both rigidity and sharpness

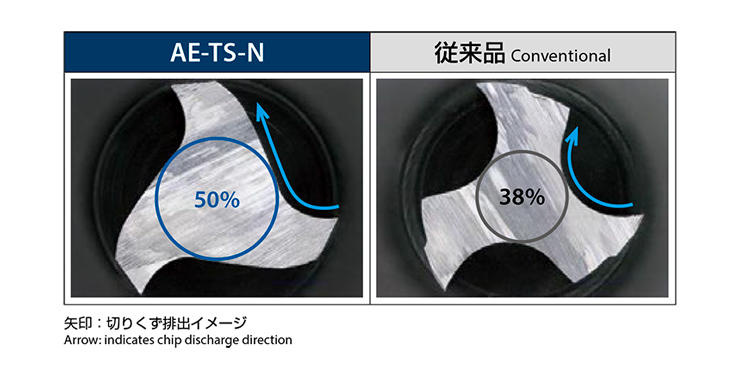

New flute form enables excellent chip evacuation

New flute form enables excellent chip evacuation

Center cutting edge specification to enable plunging

Center cutting edge specification to enable plunging

- Sharp corner edge type: for milling straight corners with no uncut residue

- AE-TL-N chipbreaker type: breaks chips into small, manageable pieces to enable uninterrupted machining

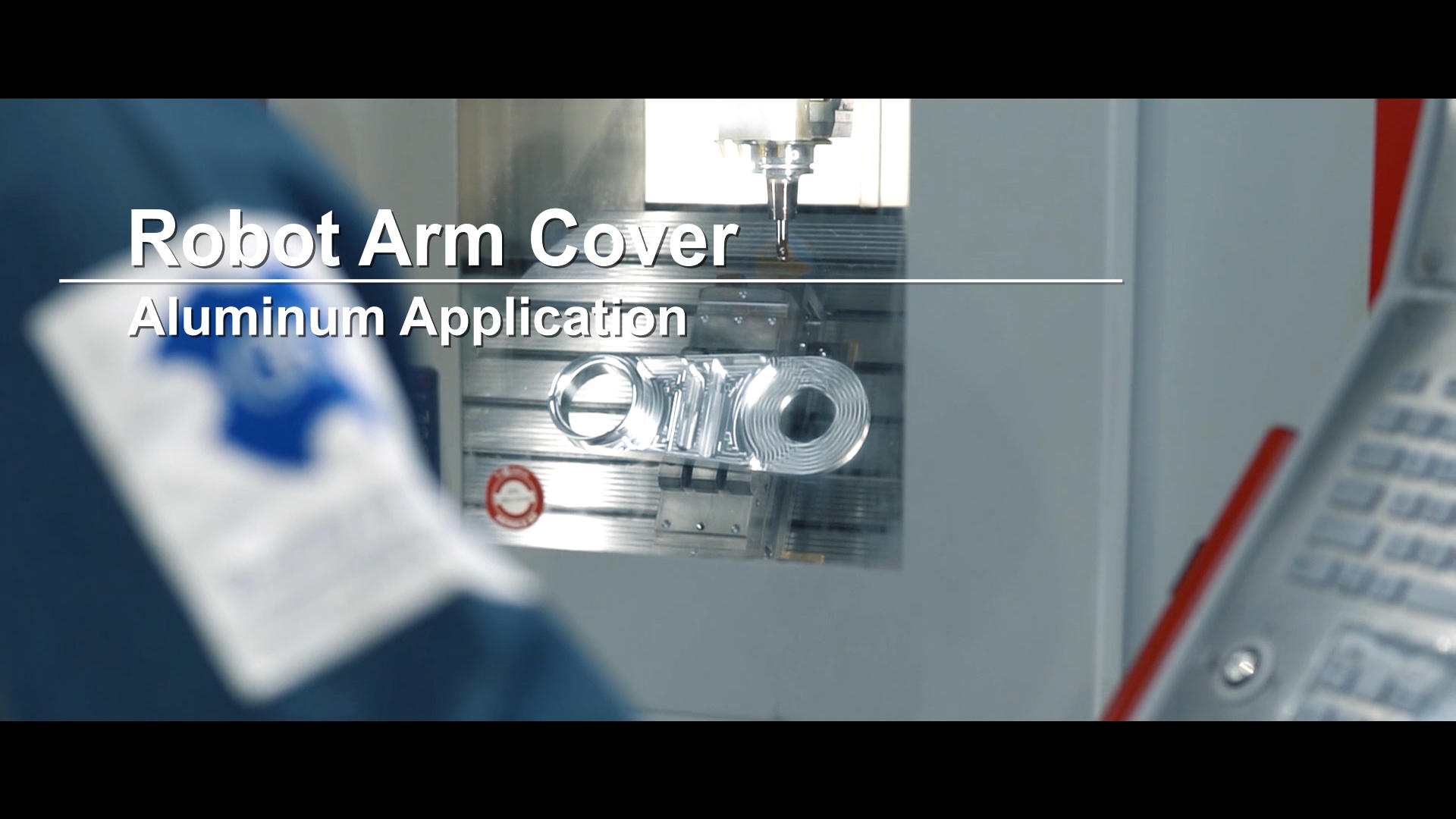

Applications

Copper Alloy・Aluminum Alloy・Plastic・Thermoplastic Resin・Thermosetting Resin

Lineup

Short Type (AE-TS-N) 1.5 x D flute length (Neck length 3 x D)

- Square Type φ1×3~φ25×75

- Radius Type φ3×9×R0.2~φ12×36×R3

- Sharp corner edge type φ1×3~φ12×36

Long Type (AE-TL-N)

- Square Type 3×D flute length φ3×9~φ25×75

- Square Type 5×D flute length φ3×9~φ25×125

- Sharp corner edge type 3×D flute length φ3×9~φ12×36

- Sharp corner edge type 5×D flute length φ3×9~φ12×60

Long Type with Chipbreaker

- Square Type 3×D cutting length φ6×18-N~φ20×60-N

- Square Type 5×D cutting length φ6×30-N~φ20×100-N

- Radius Type 3×D cutting length φ6×18×R0.3-N~φ20×60×R0.5-N

- Radius Type 5×D cutting length φ6×30×R0.3-N~φ20×100×R0.5-N

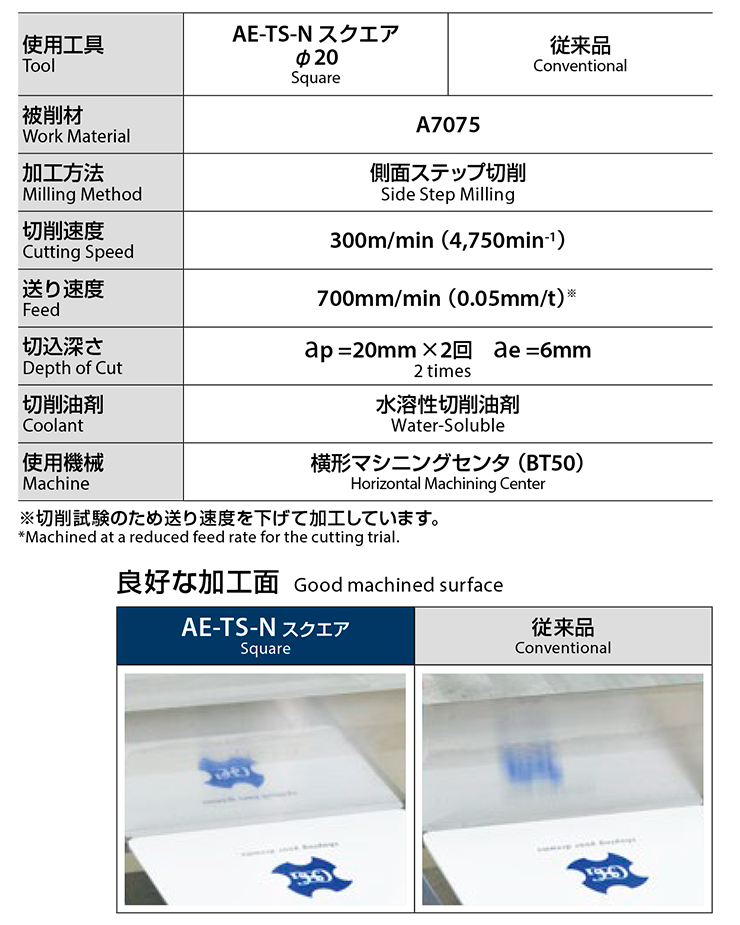

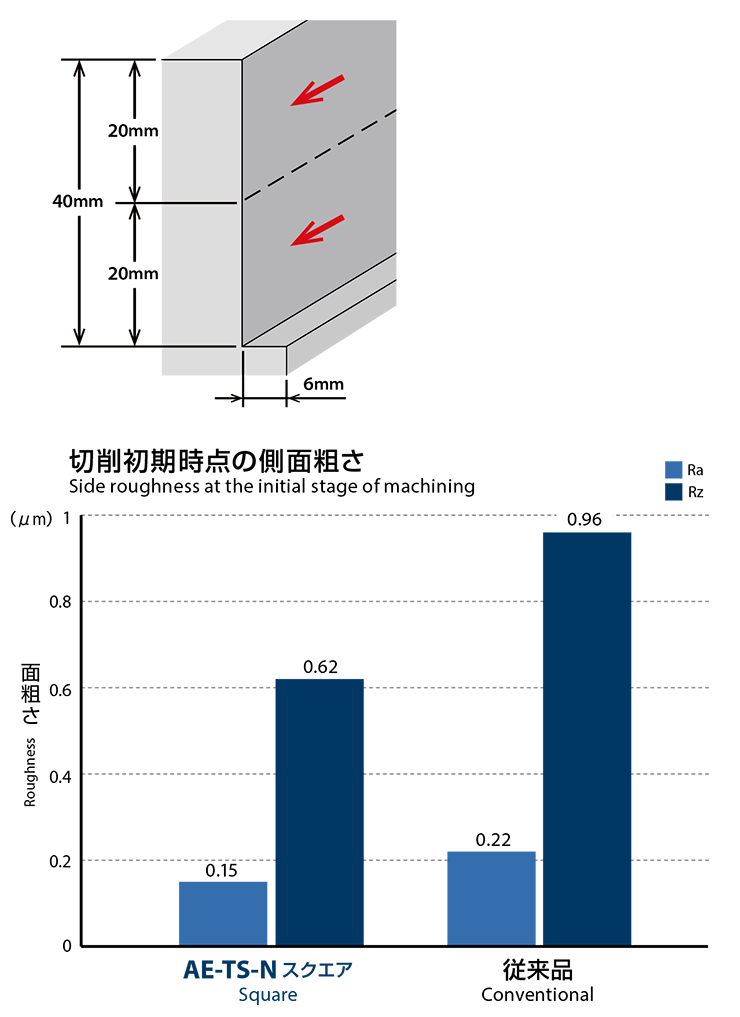

Data

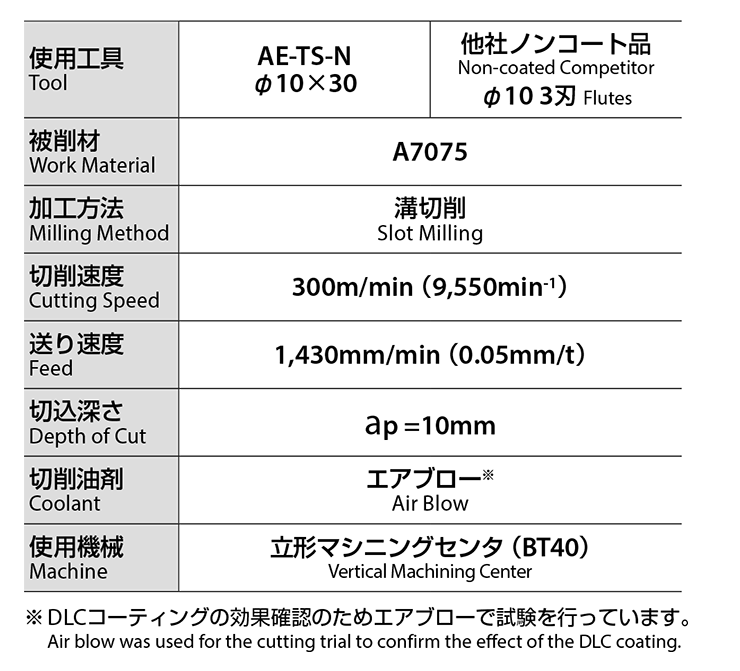

Effects by the combination of DLC coating and unique cutting edge specification for non-ferrous metal machining

Also compatible with resin processing

Achieves high efficiency and good machined surface quality even with air-blow.

Environmental Considerations

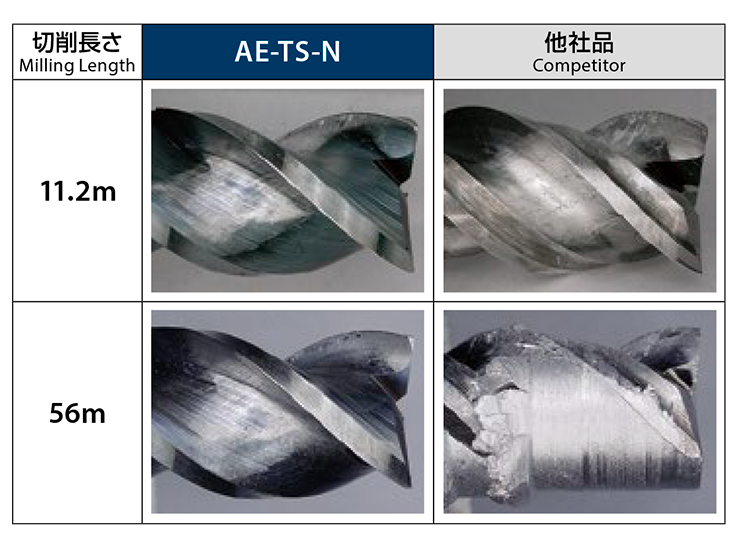

Long tool life with DLC coating

The extension of tool life leads to the reduction of waste, which contributes to resource conservation. Furthermore, a recycling-oriented manufacturing system is achieved through tool regrinding, tool recoating and material recycling.