AM-EBT・AM-CRE・AM-HFC

End Mills for Additive Manufacturing

Objects formed by “additive manufacturing (metal deposition)” using a metal 3D printer with methods such as directed energy deposition have high hardness and large fluctuations in cutting allowance. The AM-EBT and AM-CRE end mills for additive manufacturing work applications enable stable and high efficiency milling from roughing to finishing by combining a 3-dimensional negative geometry optimized for large depth of cut and OSG’s DUROREY coating with excellent heat resistance in high-hardness steel. With superior capabilities to accommodate large fluctuations in machining allowance, the AM-EBT and AM-CRE are highly effective for milling built-up welding parts with large depth of cut.

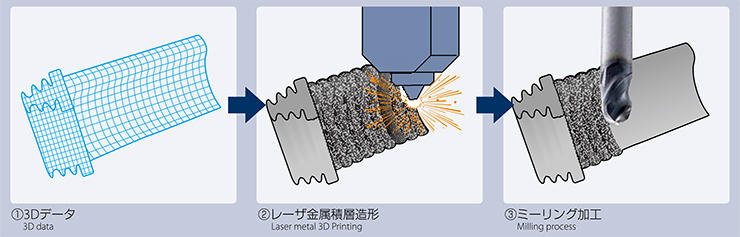

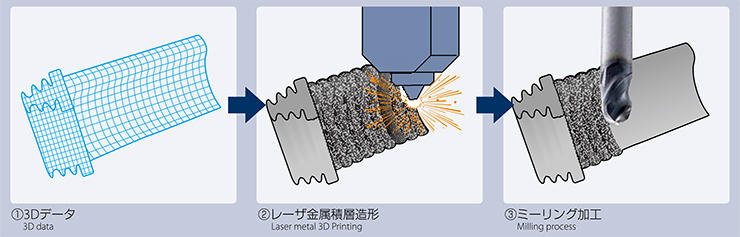

What is Additive Manufacturing?

In contrast to subtractive manufacturing processes such as cutting, where an object is formed by removing excessive materials, "additive manufacturing" deposits materials layer upon

layer by metal 3D printing to create an object.

By utilizing 3D data, short delivery and low production cost are made possible.

※ The name Additive Manufacturing was established in 2009 by the American Society for Testing and Materials (ASTM).

※ The name Additive Manufacturing was established in 2009 by the American Society for Testing and Materials (ASTM).

Features

- Newly developed DUROREY coating enables superior heat resistance and high toughness optimized for high-hardness steel milling

Three-dimensional negative geometry optimized for large depth of cut

Three-dimensional negative geometry optimized for large depth of cut

Radius type with multi-flute specification for long tool life and high efficiency

Radius type with multi-flute specification for long tool life and high efficiency

High Feed Radius Type:Composite radius cutting edge enables high feed milling

High Feed Radius Type:Composite radius cutting edge enables high feed milling

Flat cutting edge suppresses chipping of the end cutting edge and achives good machhined surface quality

Flat cutting edge suppresses chipping of the end cutting edge and achives good machhined surface quality

Applications

Pre-hardened Steel・Hardened Steel (~70HRC)・Stainless Steel・Cobalt-Chromium Based Alloy (Stellite)・Titanium Alloy・Ni-Based Alloy (Inconel 718)

Lineup

Ball Type (AM-EBT)

- R1~R10

Radius Type (AM-CRE)

- 6×R1~20×R3

High Feed Radius Type(AM-HFC)

- 4×R0.5~12×R1.5 * Exchangeable head end mill PXM PXHF-AM is also available.