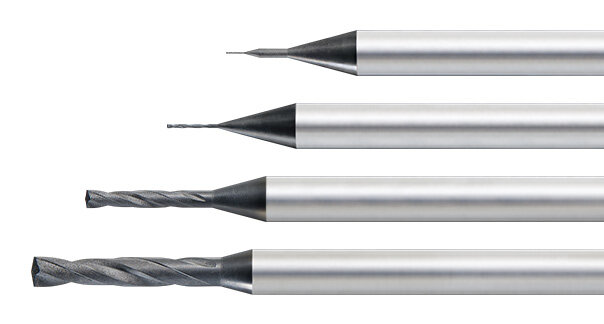

DIA-MXD

Carbide Drill for Ceramics and Glass

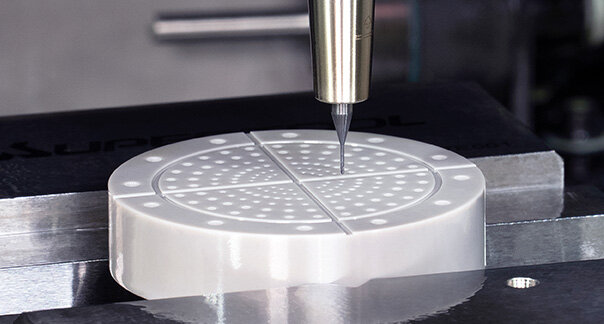

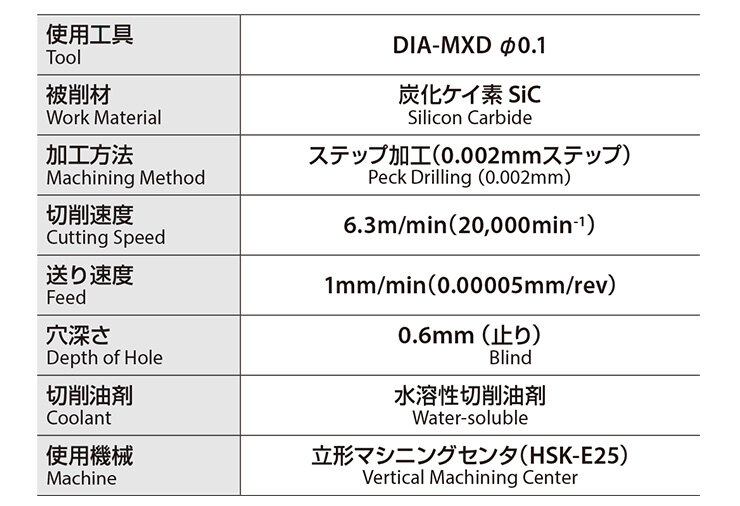

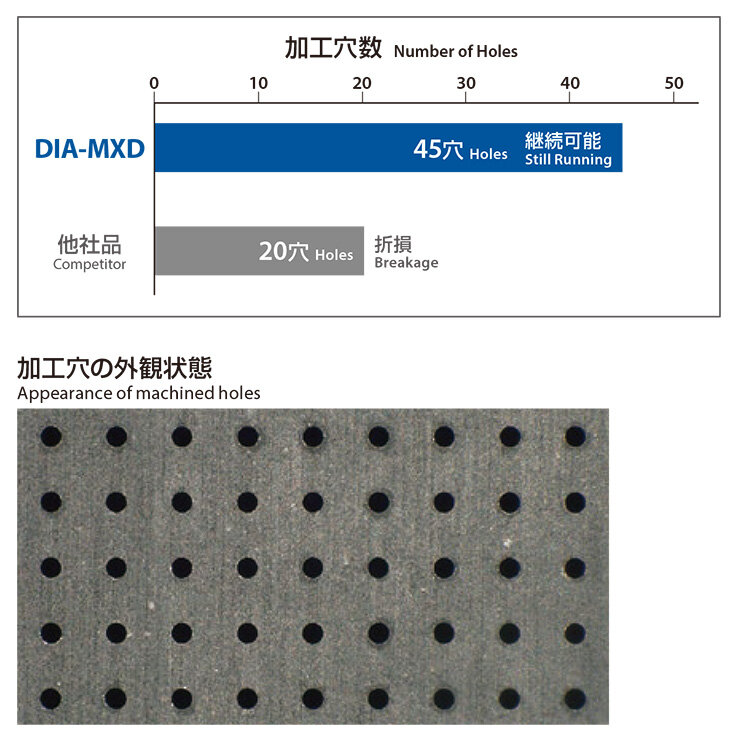

Ceramic machining for applications such as semiconductor manufacturing equipment, optical components, and electronic devices presents several challenges, including inconsistent tool life, unexpected tool breakage, and overall short tool durability. These issues are primarily caused by rapid wear progression due to sudden delamination of the coating layer. DIA-MXD effectively addresses these challenges through the integration of a highly wear-resistant HDG coating and a newly developed carbide alloy with exceptional adhesion properties. This advanced combination prevents coating delamination and delivers consistently high durability and machining stability.

Features

HDG coating

HDG coating

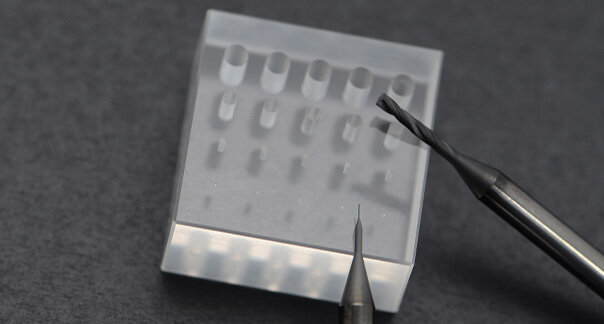

Cutting edge geometry optimized for machining ceramics and glass

Cutting edge geometry optimized for machining ceramics and glass

Applications

Ceramics・Glass