Environmentally Friendly Products

Towards sustainable development of society,

OSG proposes initiatives that can be achieved with cutting tools.

Small efforts such as using environmentally friendly coolants to reduce the number of machining processes

and tools used can be a step toward realizing a sustainable society. Increasing machining efficiency improves

machine tool availability and reduces power consumption, which in turn leads to the major effort of carbon

neutrality. OSG will continue to promote environmentally friendly initiatives, starting with cutting tools.

Taps

Taps

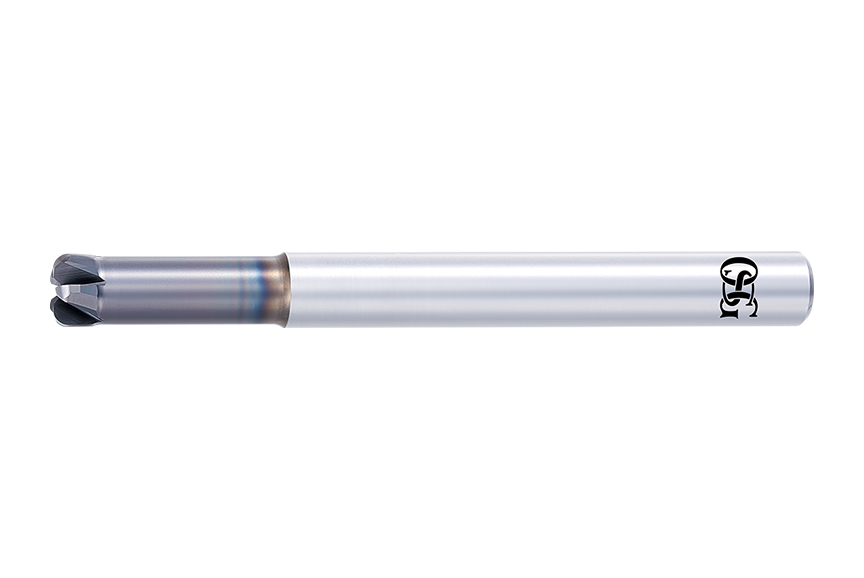

Drills

Drills

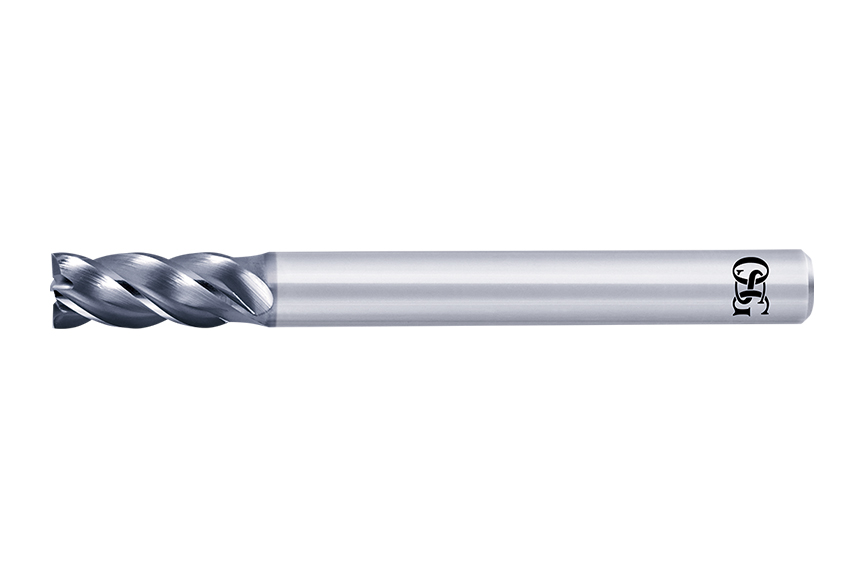

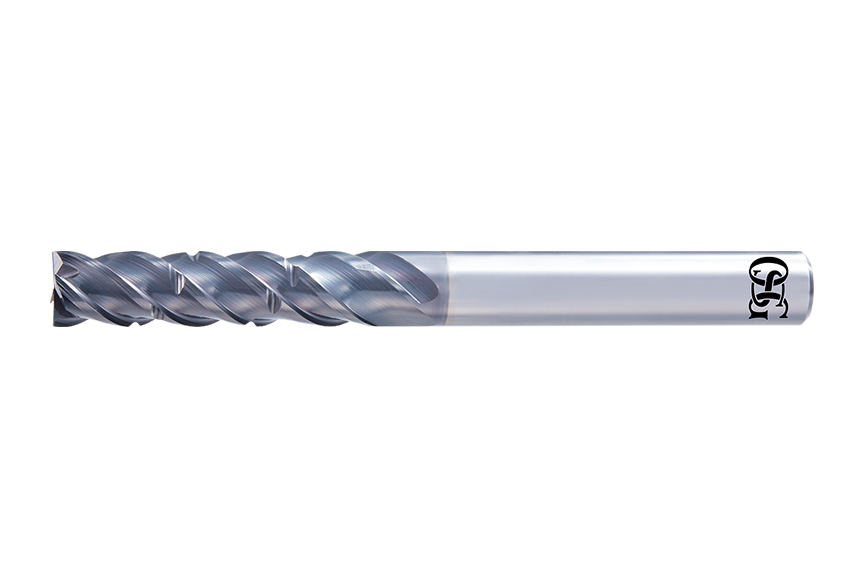

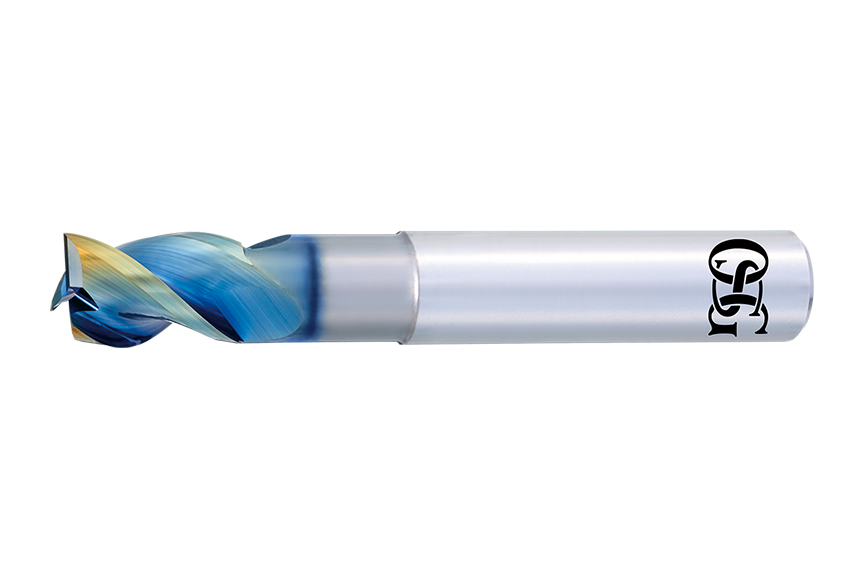

End Mills

End Mills

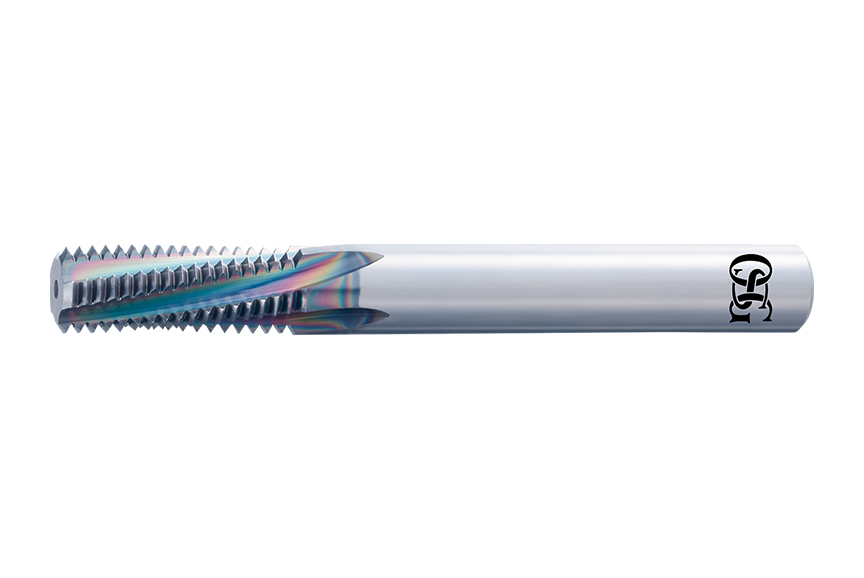

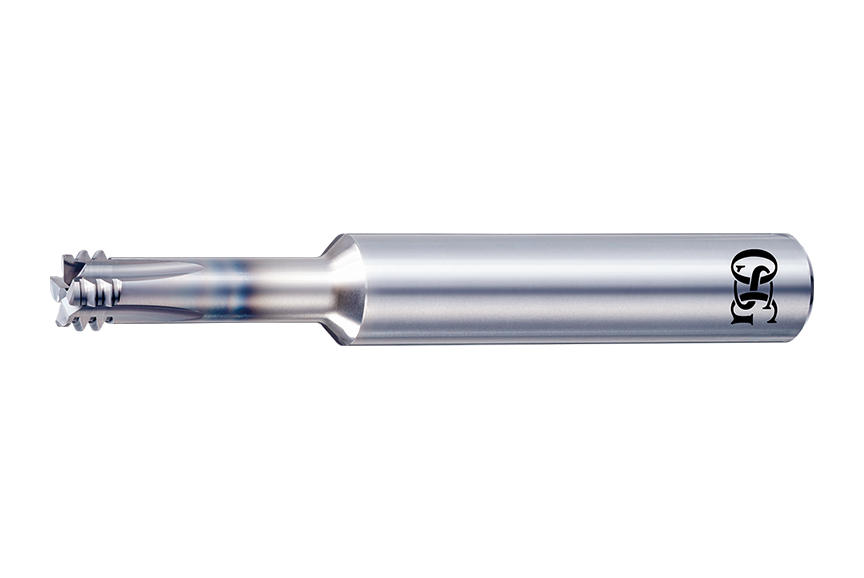

Thread Mills

Thread Mills

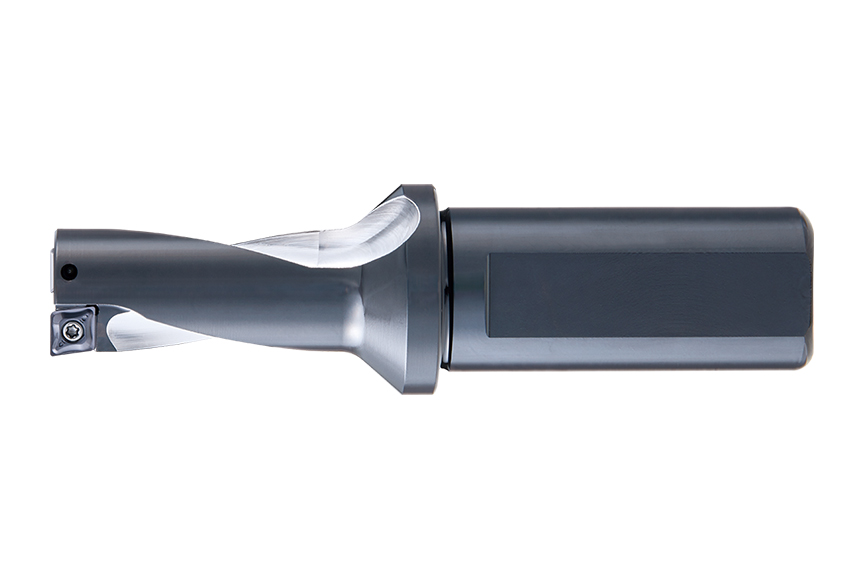

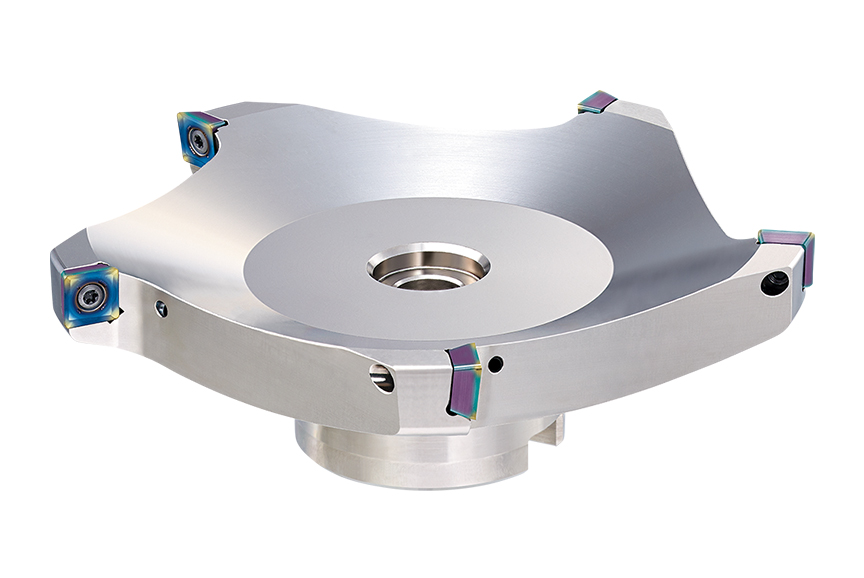

Indexable

Indexable